LAMBERTS LINIT U-Glass

In the first decades after World War II, profiled glass was used as a cheap, cost-effective solution for simple industry and commercial buildings. Today it is used for elaborate, design-driven architectural projects all over the world – such as museums, theaters, shopping centers, stadiums and many more – due to its quality, refinement possibilities, clear forms and technical variety.

LAMBERTS LINIT®EcoGlass (U-glass) is part of the training facilities of FC Bayern München and Real Madrid as well as the cable car station built for the Olympic Games in London or the Stubai glacier.

The most renowned architectural offices in the world like Steven Holl, Ian Ritchie, Rem Koolhaas and many more are planning with LAMBERTS glasses. Internationally renowned architecture awards like the LEAF prize awarded by the Leading European Architect Forum (most recently in 2016 for the Sainsbury Wellcome Center as Best Project and Best Facade) or a number of AIA Honor Awards reflect the great appreciation.

Early on our deep conviction, that you can use cast glass for many more brilliant things, encouraged us to break new ground and explore new horizons. As a result, we are the first profiled cast glass manufacturer (since 2000) to offer thermally toughened and processed U-glass of up to 7 meters as safety glass (with or without color enameling or sandblasting).

We are also constantly widening our portfolio of glass surfaces to meet the growing demands of the architects for the most aesthetic solutions. In addition, the very first point-fixed profiled glass facade (via drill hole) was successfully realized with LAMBERTS LINIT®EcoGlass.

Aesthetics – our glass surfaces

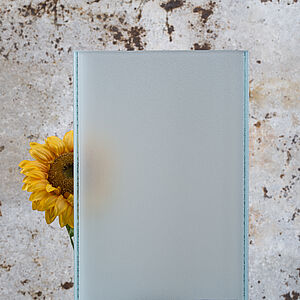

All types of LINIT glass are manufactured as standard with the décor “504” (pearl structure), which features excellent light scattering.

LINIT clarissimo is a production-technical enhancement of LINIT clear, which has been highly successful on the market for many years. LINIT clarissimo is produced using non-structured rollers and offers an additional aesthetic appeal due to its good transparency (with regard to rolled glass). However, it should be noted that the optical qualities of rolled glass cannot be compared the surface and transparency of float glass as the production techniques are completely different.

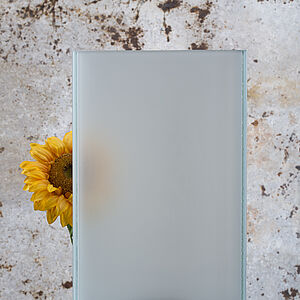

LINIT solar is characterized by a silky-smooth surface which not only allows ideal energy gain but also meets highest aesthetic demands due to its elegant appearance. This surface was developed by the Glasfabrik LAMBERTS for Steven Holl Architects, New York, and was applied in the Nelson Atkins Museum of Arts (you can find the brochure in the downloads below) for the first time. Since then LINIT solar was used not only in several follow-up projects of Steven Holl, like the Pratt Institute (New York City, USA), the Swiss Embassy (Washington, USA) and Herning Center of the Arts (Herning, Denmark), but also in many other buildings of highest aesthetic demands across the globe.

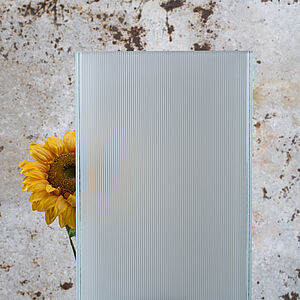

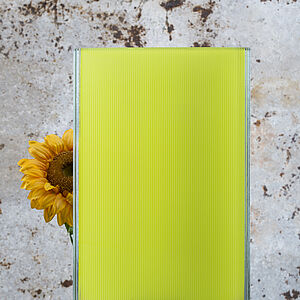

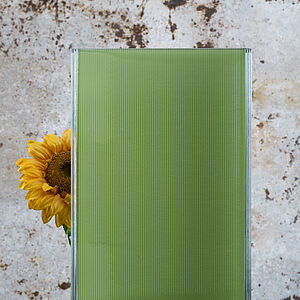

This high claim to design can also be met by the new LINIT cord. The very fine, line-shaped

surface also impresses with extraordinary elegance. Over and over, LINIT cord surprises with new astonishing and appealing optical effects when viewed from different angles. Those effects are never obtrusive but appear timelessly casual.

LINIT prismasolar is an expressive surface structure especially developed by LAMBERTS, which

– when mounted horizontally – serves as a seasonal shade and also guides the light into the depths of the room. Furthermore, this extravagant structure, which is unique on the cast glass market, also provides interesting lighting effects and unexpected optical illusions.

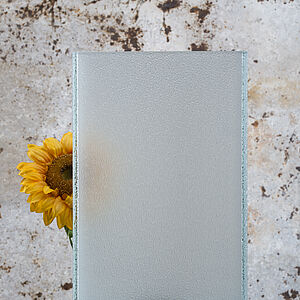

LINIT ice is a new surface structure from LAMBERTS accentuating the natural, elemental character of glass and recreates the aesthetic of ice, particularly when the glass is dulled on the inside. LINIT ice is also perfect for applications where you desire as little transparency as possible.

LINIT Magico is a pattern by Lamberts distinguished by its very finely corrugated surface structure. Objects almost entirely disappear behind this glass surface, which results in a truly unique effect and an extra ordinary visual appearance, which almost seems magical.

Concluding we would like to introduce LINIT Moiré, an interesting derivative of the LINIT product range. The basis of this surface structure is our renowned LINIT solar, which impresses through its fine, silk-like appearance. This astonishing and elegant effect is even enhanced by a vertical timeless line pattern in the new LINIT Moiré. These lines create the impression of waves within the glass, which optically add more depth and structure to buildings and facades.

The LINIT special glasses LINIT clarissimo, LINIT solar, LINIT cord, LINIT prismasolar and

LINIT ice are registered designs and protected under the patent and design protection laws of Germany.

LINIT: types of surfaces

LINIT surface finishing

Additional refinement steps allow for facades with LINIT®EcoGlass that are aesthetically a lot more interesting and attractive. These refinement steps are made using our own manufacturing facilities mostly designed by LAMBERTS for the specifics of U-glass. In doing so, we can guarantee our customers the high LAMBERTS quality we are known for.

Sandblasted

LINIT S is a U-profiled glass with a sandblasted inner surface refracting and diffusing the light completely. As a result, you can no longer see clear outlines (in contrast to directed permeability). This creates a soft, whitish hue making the LINIT facade more attractive and providing an additional lightness at comparatively low costs – especially when the glass facade is backlit.

The brilliance of such a facade can be enhanced by using so called low iron LINIT instead of standard glass: low iron LINIT, due to its lower iron content, significantly reduces the green tint usually found in standard glass and thereby accentuates the visual appearance of the sandblasting.

If desired, it is also possible to only partially sandblast the LINIT glasses to create translucent surfaces within the glass wall. Please observe the product specification of LINIT S as it is decisive of the definition regarding product quality and control. LINIT S is also available as a toughened version.

All LINIT glasses from our product range (see downloads) – except the coated glasses 1.7W,

azure and solex - can be sandblasted up to a length of 7 meters.

Watch our surface video

Color enameled

By burning ceramic colors into the inside of the glass the designer is able to create LINIT®EcoGlass facades in a variety of RAL-colors (from white via orange through to black) with more or less translucency, depending on the color. For planners and constructors preferring the whitish color of so-called etched / frosted glass we have a special type of LINIT color available, that is emulating the appearance of etched glass on the basis of ceramic colors.

The aesthetic brilliance of the glasses, just like with sandblasted LINIT S, can be considerably improved using low iron LINIT. The advantage of LINIT color lies particularly in the fact that the ceramic color is burnt into the glass at a temperature of approx. 650 C°. This results in an outstanding, lasting durability – especially combined with UV radiation – compared to conventional color applications with lower temperatures.

The simultaneous toughening of the glasses raises the maximum resistance to temperature differences according to DIN EN 14179-1 from approx. 40 K to approx. 150 K. The risk of glass breakage due to thermal stress is very likely with conventional color application. Our method shifts that risk to a temperature range that is usually not reached in standard use. Of course, the latter has to be checked by the planner in accordance with the individual project requirements.

If desired, it is also possible to only partially enamel the LINIT glasses to create surfaces with and without color within the facade. All LINIT glasses from our product range (see downloads) – except wired glass and coated glasses 1.7W, azure and solex - can be enameled up to a length of 7 meters.

It should be noted that LINIT color and LINIT S are not considered a normal building material in Germany. Therefore, approval needs to be obtained on a case-by-case basis. Our sales staff can provide you with all the test reports and product specifications needed for that.

Coated

Downloads

Brochures

Technical information

CO2 - Footprint

Production

LAMBERTS LINIT is an alkali-lime glass. It's a special form of cast glass consisting mainly of sand, lime, soda and dolomite.

These raw materials are carefully melted down in the world’s first oxygen-fired – and therefore also environmentally friendly – cast glass furnace. The glass strip taken from the oven is bent into a U-shape whilst still in its plastic phase. It is then cooled and hardened. After the closely monitored cooling process the desired lengths are automatically cut, checked for quality and packaged in batches in transport foil.

The resulting glass lengths all have an individual optical character causing a lively, light-refracting glass facade.

In contrast to float glass, LAMBERTS LINIT®EcoGlass panels never look exactly the same regarding their optical and physical properties, but of course the all meet the respective qualities and attributes listed in the LINIT product definitions.

Glass dimensions

Unlike flat glass panes, LAMBERTS LINIT profiled glass is durable and has excellent load-bearing capacities due to its U-shaped form. It can be mounted in considerable lengths (up to 7 meters depending on the wind load) without any intermediate support. LINIT LINIT®EcoGlass has such high static strength that side braces usually are not necessary. The result is a facade with a maximum of glass and a minimum of frame profiles.

LAMBERTS LINIT®EcoGlass glass is manufactured in seven basic types with varying u-profiles and dimensions. LINIT®EcoGlass special glasses with different thickness, web width and flange heights can be custom-made depending on the requirements when a certain order size is reached. Our sales staff is happy to provide you with concrete information if needed.

LINIT U-profiled glass is supplied from 100 cm up to a maximum length of 700 cm depending on the type. Within this range, fixed dimensions can be ordered to any desired length considering the production tolerances.

LINIT low iron

LINIT®EcoGlass low iron, which is produced in special production runs, is certainly the premium glass

type in the whole U-profiled glass field.

Due to its optimized low-iron raw material composition, LINIT low iron has a higher light-transmission factor of approx. 90%, as well as a higher radiation-transmission factor of approx. 88% (usual production tolerances must be taken into account).

As the glass melt of LINIT®EcoGlass low iron is normally significantly brighter and less green than the glass melt of standard production, LINIT®EcoGlass low iron is preferred by architects and designers – particularly in combination with refined surfaces (sandblasted LINIT S or color enameled LINIT color).

In these special production runs generally P26/60/7 low iron solar is manufactured for specific

projects or in stock (sale while stock lasts, reservations can be made). Other types of low-iron LINIT can be produced according to the requirements of the project they are needed for, starting at a minimum demand depending on the specific glass type.

Please contact us, if you are interested in more information.